Search

Benefits

- Automatic assembling- gas filling and pressing of insulating glass units

- Transport of the glass plates by belt, precise positioning

- Formats: rectangular as well as nearly all kind of shapes

- Processing of different glass plate dimensions, glass- and spacer widths in any sequence

- Electronic pressing power control for insulating glass units with metallic spacers

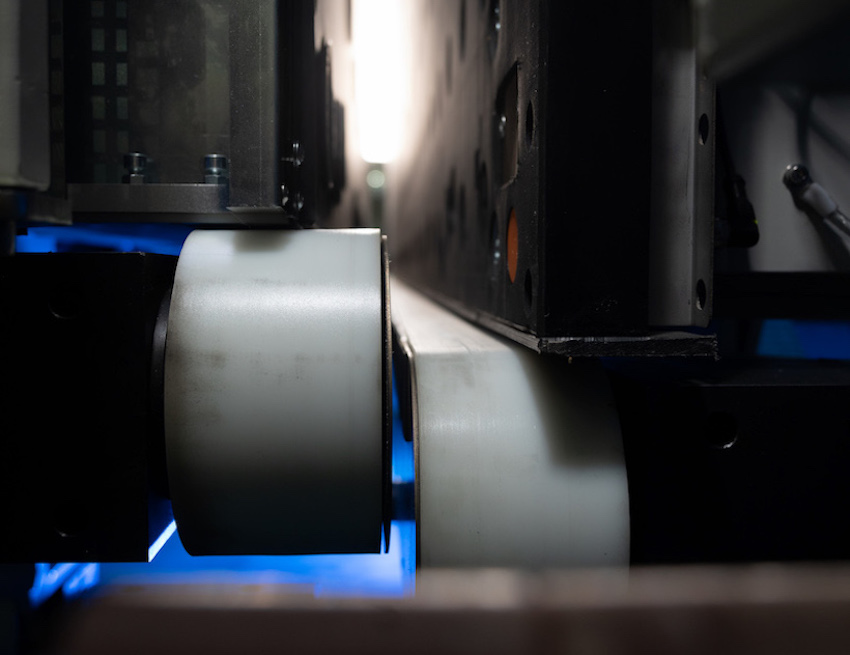

- Constant pressing with plane-parallel guided and distortion-free press-plates

- Adjustable precise press plate guiding

- Fault indicator by diagnosis-program

- Press plates can be wide opened for convenient maintenance

- Combined measuring and sequence monitoring device

- Overpressure release device

- Support system for the middle glasses

Profile

- Thickness of unit: max. 65 mm

- Glass plate thickness: max. 19 mm

- Height: 3415 mm | Depth: 865 mm | Length: 3700 mm

- Processing dimensions min: 170x350 mm

- Processing dimensions max: one-step pressing 2700 x 3500 with gas filling

- Processing dimensions max: two-step pressing 2700 x 5000 no gas filling

- P.el: 7,7 KW | Pneu: 6 bar

- Weight: app. 3400 Kg

- Gas filling rate: 95 %, subject to the use of tight spacer

Options

- Rectangular units

- Shaped units

- Double units | Triple units | Quadruple units

- From 1 to 4-sided stepped double units