Search

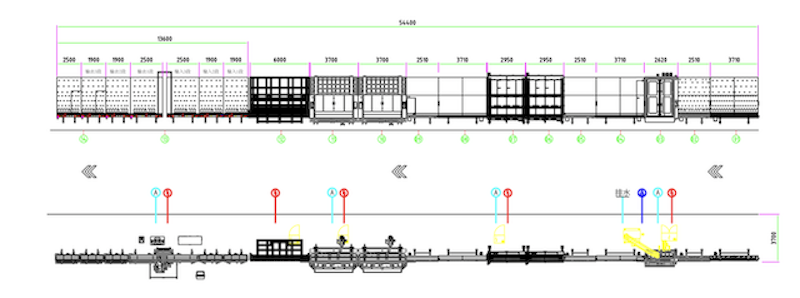

Jumbo IG LINE with automatic Gas Filling

HS FLG series Automatic Gas Filling IG Line applies Swiss technology, adopts a series of technical designs such as Ether MAC System, servo control pressing, intelligent partition, bottom inflation, etc., which can meet the continuous, rapid and high-quality production of various specifications of insulating glass. Two inspection upper frame sections cooperate with two press robots, which can be used independently or in linkage. It can realize the double station high efficiency production of small plate glass and the stable production of large plate glass.

Profile

- Working Height (m): 2.7/3.0/3.3

- Dimensions (min, mm): 190x350

- Dimensions (max, mm): 7000

- Two-step pressing dimensions (max, mm): 10000

- Spacer width (mm): 6-27

- Glass thickness: 3-40

- IG Units thickness (mm): 12-80

- Transport speed (m/min, max): 48

- Low-E: soft/hard coated auto coating detection

Options

- Rectangular units | Shaped units | Double | Triple units | Gas filling

- 3- sided stepped double units (max 250mm)

- 4-sided stepped double unit (from 65mm below up to 150mm)

- Double assembly and press robot, gas filling

- Executed for processing of 4 sided stepped units